ASU debuts manufacturing engineering doctoral program

As the initial college in the United States to present a few levels in manufacturing engineering — a bachelor’s degree, master’s diploma and newly launched doctoral degree — the Faculty of Producing Units and Networks, element of the Ira A. Fulton Educational institutions of Engineering at Arizona Point out College, is turning into a leading spot for production engineering.

“We have finished the trifecta in producing engineering education at ASU,” claims Binil Starly, professor and director in the University of Manufacturing Programs and Networks. “It is our precedence to fill curriculum gaps and supply all-inclusive programming to guidance the American manufacturing sector. The launch of this degree proves that we are on that path, but we nonetheless have get the job done to do.”

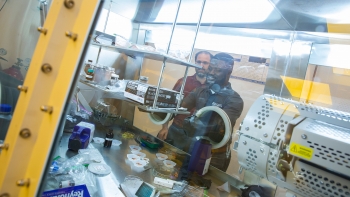

Emmanuel Dasinor, a graduate investigation associate, conducts investigation in Assistant Professor Bruno Azeredo’s lab. Image courtesy the Ira A. Fulton Schools of Engineering

Down load Total Graphic

Launching a doctoral diploma program in manufacturing engineering is quite a feat for ASU’s most recent engineering school, which formally opened its doors last tumble.

Enrollment in the manufacturing engineering doctoral degree is now open up for the fall 2023 semester. Students in the application can expect to be at the top edge of manufacturing research, finding out from research-lively faculty and leveraging the ongoing and foreseeable future investments in producing education and learning and exploration, such as more than $2 million in shared machines and $5 million in school lab assets.

Pupils will achieve deep, domain-precise production knowledge, add to the field in impactful techniques and have alternatives to collaborate with essential business partners via investigation that will take a immediate pathway to field software.

Manufacturing engineering doctoral graduates will travel study and development agendas for the innovative manufacturing economies of the 2030s, 2040s and beyond.

“It’s an exciting time to make an effects in this flourishing industry,” Starly says.

Leading the nation in producing training

Dhruv Bhate, an affiliate professor and plan chair for the new production engineering doctoral plan, thinks American manufacturing is at an inflection stage and that amplified education and learning in this discipline is a critical piece in supporting the total producing landscape.

“Nationally, there is a renewed fascination in and determination to the state-of-the-art manufacturing sector and an appreciation about its great importance to our overall economy, nationwide security and societal resilience,” Bhate suggests. “This new plan lands squarely in this space and time, rife with chance.”

Bhate provides that there’s a confluence of elements that have brought American producing to the limelight. 1st, the improved use of synthetic intelligence, or AI, and robotics next, the new resources and processing systems out there third, countrywide security and source chain interests and fourth, a greater concentration on electrical power, sustainability and the setting.

The main thrust places of the Faculty of Producing Methods and Networks align with these variables and contain producing sciences and engineering robotics, automation and autonomous devices and data sciences, AI and cybermanufacturing.

Starly believes that giving versatile, extensive and interdisciplinary producing know-how and resources to learners in these areas as a result of strong and adaptable curriculum is integral to tackling market 4. issues.

Planning pupils by means of experiential learning

To prepare doctoral students for new and approaching manufacturing difficulties, the school is featuring a curriculum packed with venture-based courses focused on addressing challenges and developing solutions that need the software of principles learned across a number of domains.

“Traditionally, manufacturing R&D teams have relied on mechanical, components, chemical, industrial and software program engineers doing the job together,” Bhate says. “We believe that unlocking innovation in the foreseeable future will progressively count not just on specialists from diverse domains working collectively, but from the innovation that emerges from the immediate exploration of suggestions that occur from a elementary knowledge of these interdisciplinary topics.”

Bhate incorporates this philosophy into the programs he teaches.

“In my additive manufacturing program, for case in point, learners full initiatives that include coming up with a component, 3D printing it and characterizing its materials homes,” Bhate states.

Task-primarily based courses usually involve marketplace engagement — yet another crucial component to getting ready pupils for careers in producing.

At present, field lover PADT Inc., a major supplier of numerical simulation, solution growth and 3D printing products and solutions and providers dependent in Tempe, Arizona, is doing work on two initiatives with producing engineering school and graduate pupils in the Producing Automation and Details Engineering Science and Technological innovation Centre, or Created STC, to place novel investigation on a immediate pathway to field software.

As the School of Producing Devices and Networks expands, so will the Designed STC, showcasing new initiatives that will be in sync with industry needs.

The enhancement of science and know-how centers at ASU has been made probable by the New Financial system Initiative, an expenditure by the condition of Arizona to advance ASU’s assignment to generate the state’s potential financial expansion and resiliency by means of engineering and technological know-how innovation and instruction infrastructure.

Market companions which include FANUC, Rockwell Automation, Honeywell, Intel and Lallemand Baking are also collaborating with the University of Producing Techniques and Networks on several producing jobs and initiatives. Strategic partnerships like these permit providers to recruit talent into their services and rapidly-monitor progressive production remedies.

Learners in the production doctoral system will also have an chance to study and collaborate in a new Heart of Excellence at ASU’s Polytechnic campus launching in 2023 and supported by various neighborhood associates, including FANUC, APT Manufacturing Alternatives, Honeywell and Klein Instructional Techniques. The center will house millions of dollars’ worth of robotics devices and aid prospects in producing investigation, field teaching, schooling, and local community upskilling and reskilling.

Arizona’s sizable producing marketplace and regional strengths in aerospace and defense, and semiconductor, automotive and strength production, will participate in a massive job in the varieties of field jobs college students will have the opportunity to effects.

Imagining the upcoming of manufacturing instruction at ASU

The manufacturing engineering doctoral application is currently supported by 15 college customers who actively conduct investigation. There are ideas to improve to 30 to 35 analysis-active faculty and enroll 140 to 160 doctoral learners in the up coming 5 decades.

In addition to the manufacturing engineering doctoral degree, the college designs to launch revamped bachelor’s and master’s diploma programs in manufacturing engineering in tumble 2024.

This calendar year, ground will split on a new 180,000-square-foot facility on the Polytechnic campus to even more help the university’s instructional and investigation mission and further investigate semiconductor manufacturing, nondestructive evaluation, products characterization and testing, and new system enhancement, amongst several other new and existing initiatives.

“We are pushing the boundaries of production education and learning in this nation,” Starly claims. “Resources set in place by our faculty, the condition and community partners will empower our learners and college to make manufacturing progress that haven’t nonetheless been described.”