NKU mechanical engineering student Collin Couch helps SD1 save big through 3D printing initiative

Sanitation District No. 1 (SD1) has begun printing its individual machines parts to drastically lower the expense of retaining its assets.

SD1 Asset Routine maintenance Technician Collin Sofa – a mechanical engineering scholar at Northern Kentucky College – is an integral part of the task, which is envisioned to help save ratepayers hundreds of dollars this yr, with much more anticipated as the 3D printing method develops.

Collin Couch demonstrates a single of the passive guideline components manufactured employing a 3D printer. (Picture from SD1)

A person of the to start with purposes of the new initiative at SD1 is in sewer inspection digicam factors. Sewer inspection cameras play a significant role in keeping Northern Kentucky’s wastewater and stormwater devices. The specialized cameras do the job with crawler robots to collect visual info of what is likely on inside sewers, making it possible for SD1 to determine difficulties and prioritize enhancement initiatives throughout the region.

SD1 spends 1000’s of dollars each year preserving these sewer inspection cameras. Raising expenditures connected with restoring this machines has been an ongoing problem for SD1.

To reduce the price tag of camera repairs, SD1 executed an in-house upkeep and maintenance plan many a long time in the past that constantly appears to be like for financial savings inside the asset upkeep office. Very last slide, personnel began to take a look at no matter if SD1 could 3D print substitution camera elements rather of purchasing pricey components from sellers.

Sofa has substantial expertise in 3D printing relationship back to his times as a student at Conner Significant Faculty. His experience ranges from printing normal-purpose goods to printing critical alternative parts for home repairs.

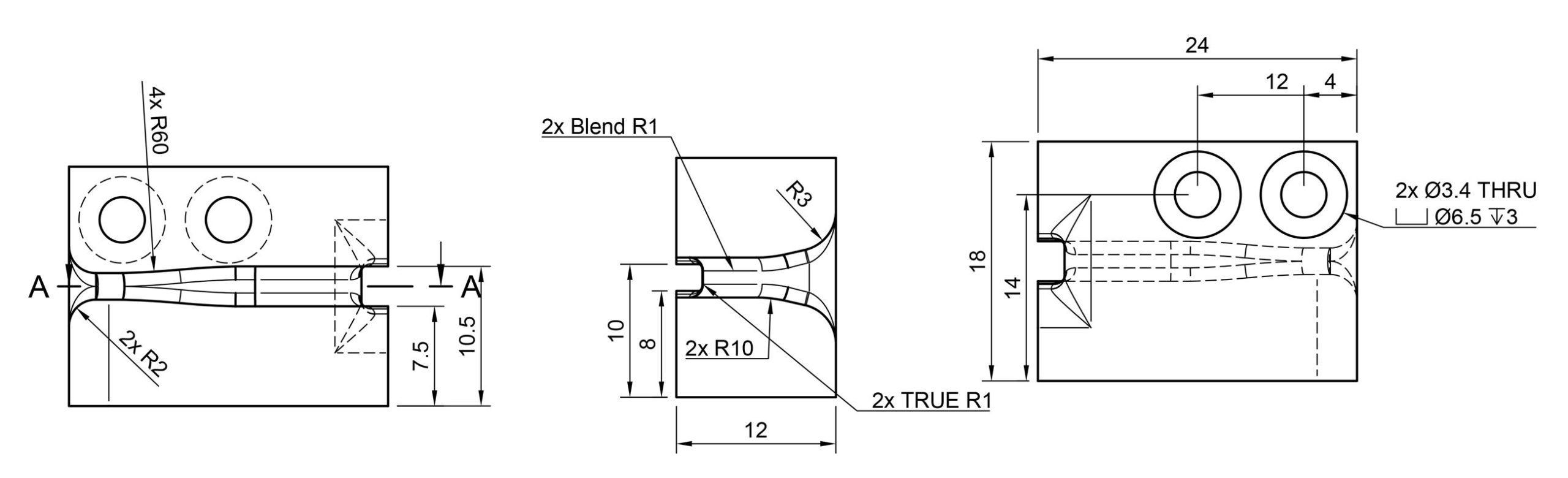

CAD schematic for the passive guideline (Image from SD1)

He 1st drew the ingredient in CAD (a 3D modeling program) and produced a 3D-printed passive manual prototype at home. He and other SD1 asset servicing staff subject-tested the prototype, experimenting with various materials and gaining worthwhile comments from SD1 digicam crews.

Following a several months, the crew developed a 3D-printed passive manual that works as efficiently as the primary aspect that was sourced from suppliers – at just a fraction of the price tag. The modest plastic guidebook had been costing SD1 about $650 for every piece, but now can be 3D printed in-residence for about 30 cents.

The transfer to in-home printing of these components will preserve SD1 virtually $40,000 every year and Couch is hunting ahead to finding other strategies SD1 can help save applying 3D printing technology.

“I’ve normally loved producing matters,” Couch claimed. “Being imaginative at this position and getting new approaches to help save money and increase SD1’s cameras has been a excellent practical experience.”

From Sanitation District No. 1