Manufacturing Engineering Degrees: Shaping the Future of Industry

Manufacturing Engineering Degrees play a pivotal role in shaping the landscape of modern industry. As we navigate an era characterized by technological advancements and global competitiveness, the demand for skilled professionals in manufacturing engineering has never been higher. This article delves into the intricacies of manufacturing engineering degrees, exploring their significance, the educational journey, career prospects, and the evolving landscape of this dynamic field.

I. Introduction

A. Definition of Manufacturing Engineering Degrees

Manufacturing Engineering involves the application of engineering principles to the design, development, and improvement of manufacturing processes. It encompasses a broad spectrum of skills, from conceptualization to production, ensuring efficient and cost-effective manufacturing.

B. Significance in Today’s Industry

In the contemporary industrial landscape, manufacturing engineering plays a crucial role in enhancing productivity, quality, and sustainability. Professionals in this field contribute to the advancement of technology and innovation, making manufacturing processes more streamlined and effective.

II. Why Choose Manufacturing Engineering?

A. Diverse Career Opportunities

One of the primary attractions of pursuing a manufacturing engineering degree is the diverse range of career opportunities it opens up. Graduates can find themselves working in industries such as aerospace, automotive, electronics, and more.

B. Impact on Innovation and Technology

Manufacturing engineers are at the forefront of technological innovation. Their expertise is instrumental in developing and implementing cutting-edge technologies, driving progress and competitiveness in various sectors.

III. Key Components of Manufacturing Engineering Degrees

A. Academic Curriculum

Manufacturing engineering programs typically offer a well-rounded curriculum covering subjects like materials science, robotics, CAD/CAM, and quality control. The academic component equips students with the theoretical knowledge needed for success in the field.

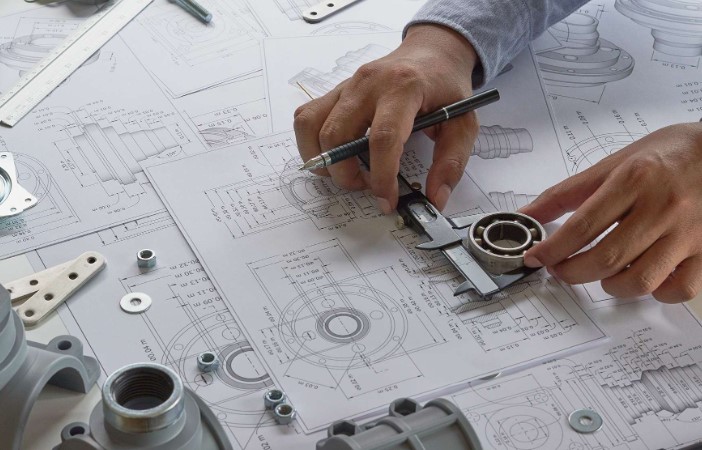

B. Practical Training and Internships

Hands-on experience is a hallmark of manufacturing engineering degrees. Internships and practical training expose students to real-world challenges, preparing them for the dynamic nature of the industry.

IV. Top Universities Offering Manufacturing Engineering Programs

A. Program Rankings

Several universities excel in offering manufacturing engineering programs. Institutions such as MIT, Stanford, and University of Michigan consistently rank high, providing students with access to world-class education.

B. Notable Features of Leading Universities

Beyond rankings, prospective students should consider factors like faculty expertise, research opportunities, and industry partnerships when choosing a program. Leading universities often boast state-of-the-art facilities and collaborations with prominent industries.

V. Career Paths After Obtaining a Manufacturing Engineering Degree

A. Job Market Overview

The job market for manufacturing engineers is robust, with a steady demand for skilled professionals. Graduates can explore roles in production management, quality assurance, process engineering, and more.

B. Specializations and Industries

Manufacturing engineering offers various specializations, allowing professionals to tailor their expertise to specific industries. Whether it’s sustainable manufacturing, robotics, or supply chain management, there’s a niche for every interest.

VI. Challenges and Opportunities in the Manufacturing Engineering Field

A. Technological Advancements

While technology presents opportunities, it also poses challenges. Manufacturing engineers must stay abreast of rapid technological advancements, ensuring they remain at the forefront of innovation.

B. Global Trends and Market Demands

Globalization has transformed manufacturing, introducing new market dynamics. Professionals in this field must navigate global trends and adapt to the evolving demands of the market.

VII. Success Stories of Manufacturing Engineers

A. Profiles of Accomplished Professionals

Highlighting success stories of manufacturing engineers adds a personal touch to the narrative. Profiles of individuals who have made significant contributions to their industries inspire aspiring engineers.

B. Contributions to Industry Advancements

Manufacturing engineers have played key roles in developing groundbreaking technologies and processes. Their contributions have led to advancements that shape industries and improve the quality of life.

VIII. Future Trends in Manufacturing Engineering Education

A. Integration of Emerging Technologies

The future of manufacturing engineering education involves the integration of emerging technologies like artificial intelligence, augmented reality, and the Internet of Things. Students must be prepared for the digital transformation of the industry.

B. Sustainable Practices and Industry 4.0

Sustainability is a growing concern, and manufacturing engineering programs are incorporating eco-friendly practices. Industry 4.0 initiatives, emphasizing automation and data exchange, are also reshaping the manufacturing landscape.

IX. Tips for Prospective Manufacturing Engineering Students

A. Choosing the Right Program

Selecting the right manufacturing engineering program is crucial for a successful career. Consider factors such as faculty reputation, available specializations, and opportunities for hands-on experience when making your decision.

B. Excelling in Academic and Practical Components

Success in the field requires a balance of academic knowledge and practical skills. Strive to excel in both aspects, as employers value a well-rounded skill set in manufacturing engineering professionals.

X. Industry Collaborations and Partnerships

A. Importance of Industry Connections

Manufacturing engineering programs that foster strong ties with industries provide students with invaluable opportunities. Collaborations with companies enhance the practical relevance of the education and facilitate smoother transitions into the workforce.

B. Real-world Applications and Projects

Engaging in real-world projects and applications allows students to apply theoretical knowledge in practical settings. Industry collaborations often lead to internships and job opportunities for students.

XI. The Role of Research in Manufacturing Engineering Programs

A. Faculty Contributions

The caliber of faculty research is a crucial aspect of any manufacturing engineering program. Institutions with faculty actively contributing to research and development ensure students are exposed to the latest advancements in the field.

B. Opportunities for Student Research

Programs that encourage student research contribute to the overall growth of the field. Engaging in research projects allows students to delve deeper into specific areas of interest and contribute to the academic community.

XII. Testimonials from Manufacturing Engineering Graduates

A. Personal Experiences and Insights

Sharing personal experiences and insights from manufacturing engineering graduates adds authenticity to the article. First-hand accounts provide readers with a glimpse into the challenges and triumphs of pursuing a manufacturing engineering degree.

B. Lessons Learned and Advice for Aspiring Engineers

Graduates often have valuable lessons to share. Their advice for aspiring engineers can guide prospective students in navigating the academic and professional challenges associated with manufacturing engineering.

XIII. Funding and Scholarships for Manufacturing Engineering Students

A. Financial Support Options

Education can be financially demanding, but there are various funding options available for manufacturing engineering students. Explore scholarships, grants, and financial aid programs to ease the burden of tuition costs.

B. Criteria for Scholarship Applications

Understanding the criteria for scholarship applications is crucial. Some scholarships may be merit-based, while others consider financial need. Thoroughly research and apply to relevant opportunities to support your education.

XIV. Comparison with Other Engineering Disciplines

A. Distinct Features of Manufacturing Engineering

Highlighting the distinct features of manufacturing engineering sets it apart from other engineering disciplines. Understanding these differences helps prospective students make informed decisions about their career paths.

B. Complementary Roles in Various Industries

While manufacturing engineering has its unique focus, it often collaborates with other engineering disciplines. Exploring how these fields complement each other provides a holistic understanding of the engineering landscape.

XV. Conclusion

A. Recap of Key Takeaways

In conclusion, manufacturing engineering degrees offer a dynamic and rewarding path for individuals passionate about shaping the future of industry. The comprehensive education, diverse career opportunities, and the ever-evolving nature of the field make it an exciting choice for aspiring engineers.

B. Encouragement for Prospective Students

To prospective students, embark on this journey with enthusiasm and dedication. Manufacturing engineering is not just a degree; it’s a gateway to contributing to the technological advancements that define our world.

Unique FAQs About Manufacturing Engineering Degrees

- Q: What makes manufacturing engineering different from other engineering disciplines? A: Manufacturing engineering focuses on optimizing production processes, ensuring efficiency and quality, while other disciplines may have different areas of emphasis.

- Q: Are there specific industries where manufacturing engineers are in high demand? A: Yes, industries such as aerospace, automotive, electronics, and renewable energy have a high demand for skilled manufacturing engineers.

- Q: How can students stay updated on emerging technologies in manufacturing engineering? A: Students can stay updated through industry publications, attending conferences, and participating in workshops and webinars.

- Q: What role does sustainability play in manufacturing engineering programs? A: Sustainability is increasingly important, and many programs incorporate eco-friendly practices and address the environmental impact of manufacturing processes.

-

Q: Are there opportunities for international exposure in manufacturing engineering programs? A: Yes, many programs offer exchange programs, internships abroad, and collaborations with international industries, providing students with global exposure.