Using additive manufacturing to detect counterfeit parts

Guaranteeing made goods and components have not been copied and replaced illegally by counterfeited products is a substantial-priority worry of the producing and protection industries in the U.S. and around the environment.

A opportunity answer would hold extensive-achieving impacts and implications in many areas ranging from maximizing biomedical implants to preserving nationwide protection belongings.

Texas A&M University researchers have created a method of imprinting a hidden magnetic tag, encoded with authentication information, in just created components in the course of the aspect fabrication process. The revolutionary procedure retains the prospective to expose counterfeit items more simply by changing physical tags—such as barcodes or quick response (QR) codes—with these concealed magnetic tags, which provide as long-lasting and special identifiers.

The venture, titled “Embedded Info in Additively Created Metals via Composition Gradients for Anti-Counterfeiting and Supply Chain Traceability,” is a school husband or wife job supported by the SecureAmerica Institute. It includes researchers from the Department of Resources Science and Engineering and the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M.

The staff not long ago revealed its investigation in the journal Additive Manufacturing.

The college investigators on the job include Dr. Ibrahim Karaman, Chevron Professor I and office head of the resources science and engineering section Dr. Raymundo Arroyave, professor of products science and engineering and Segers Family members Dean’s Excellence Professor and Dr. Richard Malak, associate professor of mechanical engineering and Gulf Oil/Thomas A. Dietz Profession Enhancement Professor. In addition to the faculty, Dr. Daniel Salas Mula, a researcher with the Texas A&M Engineering Experiment Station, and doctoral university student Deniz Ebeperi—both users of Karaman’s analysis group—have worked on the task. The crew has also collaborated with Dr. Jitesh Panchal, professor of mechanical engineering at Purdue University.

Ensuring security and trusted authentication in production is a vital nationwide concern, with the U.S. investing billions of dollars in manufacturing. With out this sort of a method commonly out there, it can be almost difficult to differentiate an genuine section or part from its counterfeit duplicate.

“The problem is that when I occur up with an strategy, system or section, it is incredibly easy for other people to copy and even fabricate it substantially additional cheaply—though it’s possible at a decrease excellent,” Karaman said. “Occasionally they even put the exact same brand title, so how do you make guaranteed that product isn’t really yours? (The embedded magnetic tag) provides us an opportunity and a new device to make sure that we can guard our protection and production industries.”

The staff is utilizing metallic additive manufacturing procedures to complete its goal of effectively embedding readable magnetic tags into metal parts devoid of compromising on performance or longevity. Scientists utilised 3D printing to embed these magnetic tags below the surface into nonmagnetic steel hardware.

Other programs for this system contain traceability, excellent command and far more, mostly dependent on the industry in which it is used.

At the time embedded into a nonmagnetic merchandise, the magnetic tag is readable using a magnetic sensor device—such as a smartphone—by scanning close to the right site on the product, allowing for the selected info to be accessed by the consumer.

When other strategies exist for imprinting info, they largely call for sophisticated and high-priced machines that introduces a barrier to true-globe implementation.

“Distinct methods have been applied to consider to domestically transform the attributes of the metals during the producing course of action to be ready to codify information within just the section,” mentioned Salas Mula. “This is the first time that magnetic houses of the content are becoming utilized in this way to introduce information and facts in a nonmagnetic section, specially for the 3D printing of metals.”

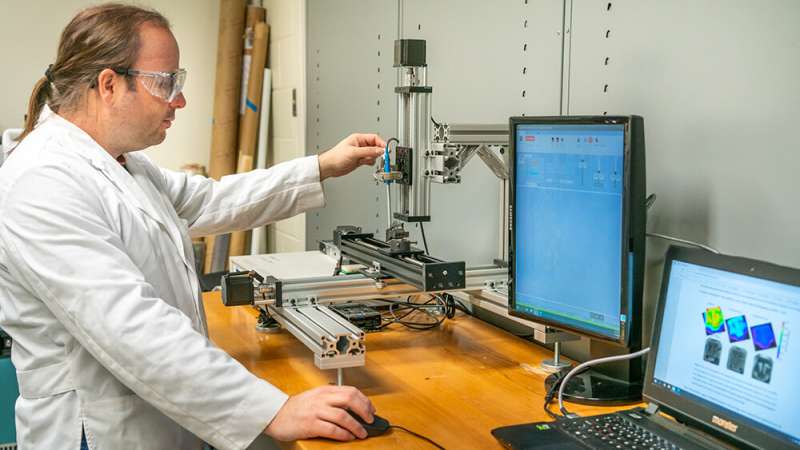

Ebeperi reported that to map the magnetic looking at of the aspect, the team established a custom 3-axis magnetic sensor able of mapping the area and revealing the regions where by the embedded magnetic tag was accessible.

Although the system is a lot more protected than a bodily tag or code located on the exterior of an item, the staff is continue to doing work to enhance the complexity of the method’s security.

As the challenge continues, Karaman said the up coming steps consist of establishing a more safe process of looking at the details, possibly by means of the implementation of a bodily “dual-authentication” necessitating the consumer to implement a precise treatment method or stimulus to unlock accessibility to the magnetic tag.

Additional info:

D. Salas et al, Embedding concealed info in additively produced metals by means of magnetic assets grading for traceability, Additive Production (2022). DOI: 10.1016/j.addma.2022.103261

Citation:

Utilizing additive manufacturing to detect counterfeit pieces (2022, December 16)

retrieved 17 December 2022

from https://phys.org/news/2022-12-additive-counterfeit.html

This document is issue to copyright. Apart from any good dealing for the purpose of non-public examine or investigate, no

part may possibly be reproduced without the need of the prepared permission. The articles is presented for information reasons only.